What does sustainable, Australian-based manufacturing look like?

It was wonderful to be invited along for a tour with Interface, including both their showroom in Surry Hills and their mill in Minto – which is one of the last carpet manufacturing factories in Australia.

While many companies are catching up to today's expectations of sustainable practices, it's so inspiring to see those like Interface, who have been working proactively for decades to minimise their environmental footprint.

Though it might seem small-scale in the context of the broader construction industry, Interface recognise that their products will have an impact, and are dedicated to making it a positive one.

They have set a goal of becoming a Carbon Negative company by 2040 – meaning they capture and store more carbon than they emit. From continually reducing manufacturing waste, to using bio-based materials that store carbon, the thought and innovation that underpins their processes is admirable.

Interface also offer a program that reclaims used Interface carpet tiles and finds a new purpose for them in charities, small businesses and residential projects. Where they can't be repurposed, the recyclable nature of their products allows them to be used to produce new carpet tiles – so nothing goes to landfill.

Their foundation of sustainable practice means that when Interface products leave the factory, the embodied carbon within them is dramatically reduced, sometimes to less than 50% of the industry average. Multiplied across countless projects, this reduction makes a meaningful impact, contributing to a lower carbon footprint for the organisations and buildings that use the products.

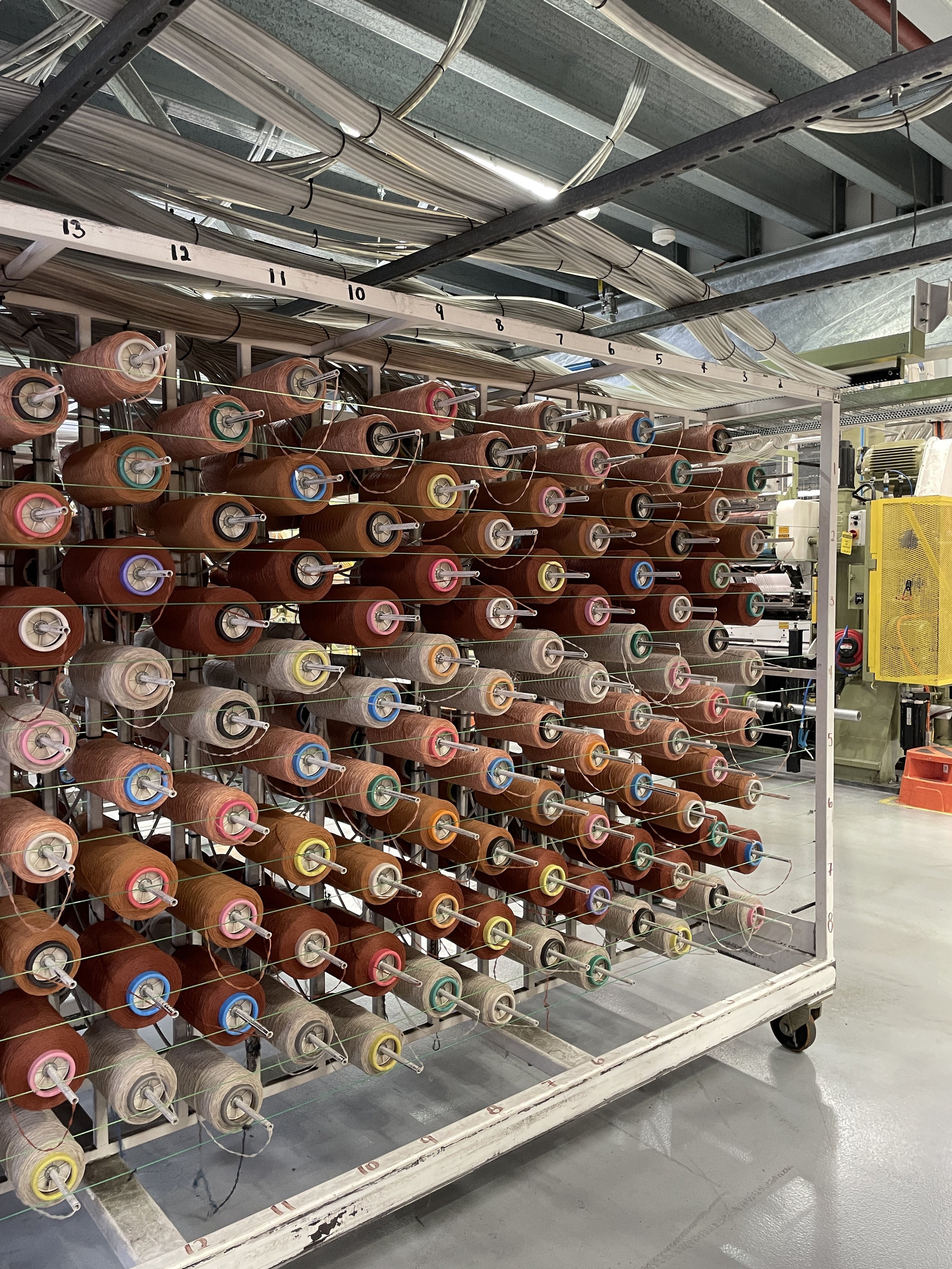

What's so important, especially from our perspective as interior designers, is that this commitment to sustainability doesn't come at the expense of high-quality design. Interface has an impressive, refined process and offers almost endless options for custom carpet – which can be designed, rendered, sampled and documented. Not only is this useful for creating beautiful tailored spaces, but it also removes a barrier to specifying sustainable products: if any colour, style or pattern you can think of can be manufactured responsibly, it's that much easier to reduce the environmental impact of a project.

For us, an in-depth understanding of how products are made will always enhance our ability to do our jobs well. Learning what can be achieved through sustainable processes and Australian-based manufacturing raises the bar across the industry - we want to see more and more companies taking their environmental impact seriously, and going above and beyond the expectations of sustainability.